Integrity of the Upper: Running Shoe Design Series, Pt. 4

We’ve talked about the last (being the first part of the running shoe design process), midsole, outsole, and today, we’re closing out the running shoe design series with the upper.

Once the last, midsole and outsole are all completed, perhaps the most creative part of footwear design is the upper. In fact, most designers create sketches of the upper before any technical work has commenced. A designer will likely have a sketch pad full of ideas before embarking on any computerized technical software, such as Adobe Illustrator, to begin the 2D tech pack process.

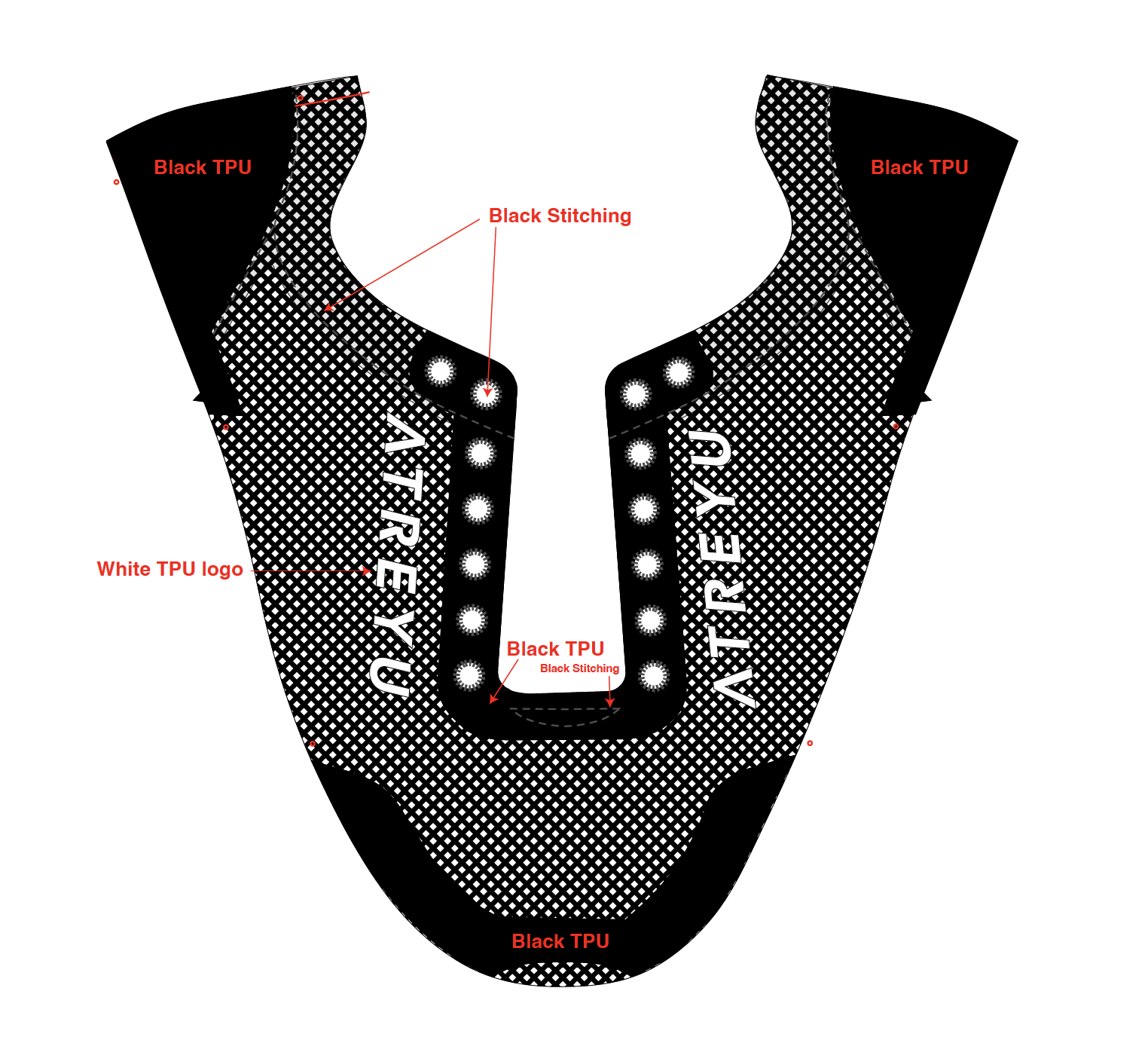

When designing an upper, the process often incorporates using a pattern outline. Before any fabric is cut, the designer will create the digital flat lay image within the tech pack.

The design files are then sent to the sample rooms for a “pullover” sample of the upper to begin fitting the design on the last. Minor tweaks are made until the final design fits tight and even over the shape of the last.

There are often many layers and ideas incorporated into an upper design. Materials like TPU (thermoplastic polyurethane) can be incorporated into many aspects of the upper such as a toe guard, lateral/medial structural supports or logo overlays. For materials like polyester, sublimation printing can be incorporated for high-resolution graphics or colorway gradients. Foam can be die-cut for heel and tongue construction, padding and hot-spot resistance. The upper creativity can often seem boundless when considering the endless array of materials and combinations.

Once the upper 2D pattern and samples are created, they are bound to resemble the foot’s shape by sewing or gluing the “Strobel board.” This piece of material binds the upper into a shape that can be fixed to the midsole part by either sewing or using adhesives.

When the upper design is complete, the “lasting” process begins. This is the final process of creating footwear, which incorporates unifying all parts with the help of a “lasting” machine. The last is fixed to the lasting machine, the upper is draped onto the last and the midsole combo is pressed onto the upper with adhesives. Once this process is complete, the shoe is finalized!

In essence, the upper is the most creative aspect of the shoe design and often receives a large portion of the glory in the market. I believe it represents style and personal fulfillment as a philosophical parallel in our personal lives. Once we achieve an inherent knowledge of the fundamental aspects of our mind and body, we can then dress for success; it’s all about integrity.

Even the most fabulous style can’t cover up an unhealthy lifestyle. What’s underneath matters. Only once we do the work on the inside, we can then exhibit our style to the world and add personal flair. This is what makes footwear design so beautiful. It is inherently technical but cloaked in excess amounts of style to make an impression in the market.

Before we close out, I want to thank you for reading this series of articles. I had a great time challenging myself to balance the technical aspects of footwear design with my own personal style of presenting the material as entertaining. I am grateful for your time, and I thank you for letting me have the opportunity to build my self-esteem in this project.

Next time you buy a pair of running shoes, I hope you can find some of this information helpful in your endeavors. Until next time, I hope you all enjoy some memorable miles!

About the Author

Michael Krajicek is the founder, CEO and designer of Atreyu shoes. He participates in marathons and triathlons and leads the Atreyu Run Club in Austin. When not participating in endurance sports or training, Krajicek enjoys photography and playing music.